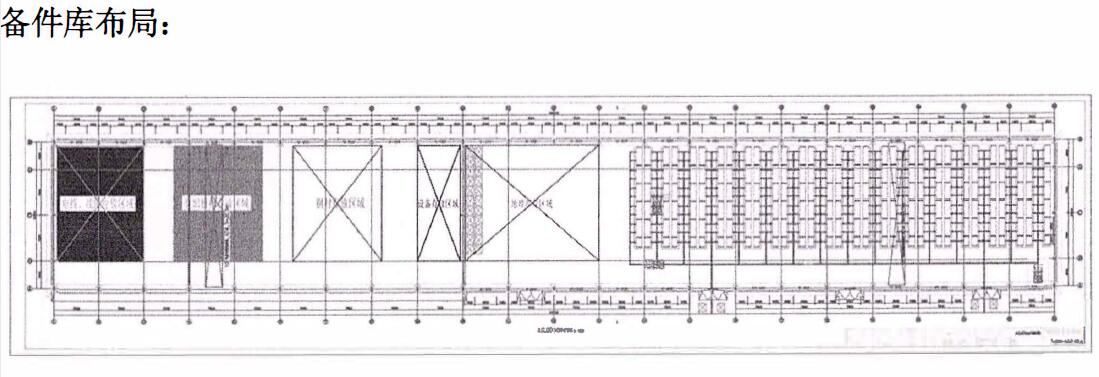

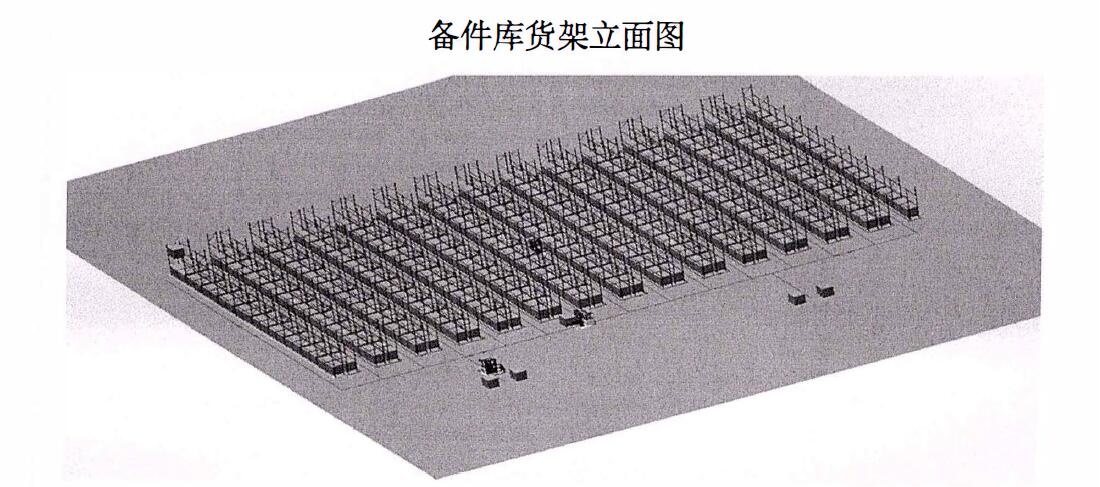

The second warehouse of materials stores raw and auxiliary materials with a unit weight of less than 1.5 tons and a relatively small volume. It is proposed to use three tiered three-dimensional shelves, equipped with two AGV trolleys and charging devices; The spare parts warehouse (3 # warehouse) is divided into two parts, one part of which is a three-layer three-dimensional shelf, the other part is stacked to store all large and small spare parts, and two AGV trolleys are equipped. No. 4 warehouse is mainly a storage area for large equipment, steel, large cables and other large materials and waste materials. This warehouse is equipped with vehicles to receive and send goods; a separate warehouse is set for dangerous chemicals such as Oxyacetyleneand lacquer pine perfume, both of which are sent and received manually, but account counting is included in the entire intelligent management system.

In terms of storage capacity and access efficiency compared to the traditional shelf warehouse has a qualitative leap, but also to meet a variety of special industry access requirements, is also a substantial reduction in labour costs.

Project information: This case customer is a focus on the overall sanitary ware research and development, production, sales and service of large integrated enterprises, products exported to many countries and regions around the world, committed to providing users with personalized, high-end customized services, for consumers to create a better quality of life.

With the continuous expansion of the production scale of enterprises, traditional production methods have been unable to meet the needs of enterprises, in order to fully carry out intelligent manufacturing transformation and upgrading, to achieve the "production warehousing distribution and packaging" of the whole process intelligent, to create the future "super smart factory", customers and Yufeng intelligent reached cooperation, for the strategic goal of transformation of smart factory layout in advance.

The intelligent logistics system solution of the whole plant includes intelligent logistics systems such as warehouse storage system, conveying system, robot palletizing system, AGV distribution system, and intelligent logistics software management systems such as WCS and WMS, seamlessly connecting the factory production line. The whole process of logistics operations such as material packaging, storage, sorting and distribution of raw materials, semi-finished products and finished products is efficiently connected with production and assembly, and the integration of automation, Internet of things and other technologies is used to break data barriers, improve intelligent management level, and realize efficient coordination of picking, storage and distribution.

As a global security glove head enterprise, it is also a global leader in security products.

Project type: Set multiple types of products according to different scenarios and efficiency respectively into different product combinations. Set up an intelligent project from raw material storage to production line production to finished product packaging to finished product delivery. The actual business scenario involves the entire campus of the customer. A dozen buildings in all. Realized smart park, light-out factory.

Customer introduction: is a research and development, production, sales, service in one of the modern furniture manufacturing enterprises. Mainly engaged in sofa, bed products and supporting household goods, positioning in the "fashion, light luxury" product style. Products are exported to Europe, the United States, the Middle East and other countries and regions, serving tens of thousands of happy families.

Basic project information: Automated warehouse equipment, the system is divided into 2,600 pallet warehouse, 2,300 pallet warehouse, a total of 10,348 storage locations, the system is composed of 11 (5+6) stacker, 8 (2+6) RGV,4 AGV, electrical control system, WCS system, WMS system, storage capacity of 400 container cabinets automated intelligent warehouse, The annual production capacity has reached 4,000 containers.

Customer introduction: As a global TV OEM, is the world's top three TV OEM.

The combined automated warehouse of stacker crane and four-way shuttle can perfectly combine to realize the dense storage of the vertical warehouse, which has the characteristics of high dynamic density and space saving. Through the cooperative work of shuttle and stacker crane, the warehouse utilization rate and storage density can be improved compared with the traditional roadway stacker warehouse, and the warehouse unmanned operation can be realized through WMS management and WCS dispatching.

The components of new energy vehicles are characterized by a wide variety and differing specifications. Managing them by zones poses significant challenges, and the traditional warehousing model for automotive parts logistics has reached its limits, resulting in low space utilization.

To address the warehousing issues in the new energy vehicle parts industry, Yufeng Intelligent employs information technology to achieve automated, digitalized, and intelligent warehouse management. By optimizing space utilization and storage methods, they have constructed an automated stacking crane warehouse, using pallet/cage storage systems and flexible conveying equipment, complemented by WMS and WCS software systems.

Compatibility with Various Pallet Specifications and Flexible Operations: Due to the different models and brands in the automotive industry, various pallet specifications are required, and uniform pallet sizes cannot be achieved. This project uses a special design that allows the equipment to be compatible with multiple pallet specifications, enabling flexible operations.

Efficient Storage of Purchased Parts and Semi-Finished Products:

Yufeng Intelligent deploys multiple smart AGVs. The finished products are automatically delivered to the required production locations by AGV. The AGV scheduling system, MES system, WMS system, and real-time Internet control of each machine ensure the efficient and reliable operation of each logistics system.